Continuous Extrusion Cladding for Aluminium Clad Steel Wire

Cable Sheath Line

Continuous Extrusion Cladding for Aluminium Clad Steel Wire

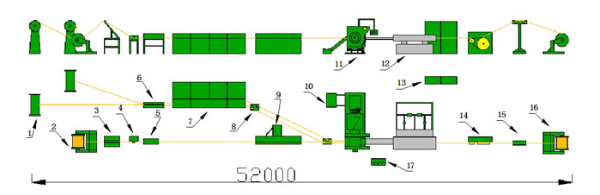

| 1. Aluminum Rod Pay-off Machine 2. Straightening Unit 3. Washing Machine 4. Steering Wheel 5. Steel Core Pay-off Machine 6. Buffer System 7. Guide Pulley 8. Straightening Unit 9. Induction Heater 10. Continuous Extrusion Machine 11. Cooling and Drying System 12. Traction Wheel 14. Take-up Machine 15. Hydraulic and Lubrication System 16. Electric Control Cabinet 17. Operation Console |  |

| Aluminum clad steel (AS) process adopts continuous extrusion tangential direct cladding technology to continuously clad aluminum on the exterior surfaces of treated steel core wires directly. Then bi-metal synchronous deformation process is adopted to draw the wires into required sizes. The AS wires produced by this technology can satisfy the demands of IEC standard and ASTM standard. |  |

|

As a trusted provider of continuous rotary extrusion solutions for non-ferrous metals, we have especially designed this aluminum clad steel wire extrusion line to ensure highly efficiency cable conductor production. This production line fulfills all steps including material payoff, feeding, cleaning, cooling, and coiling. The main unit of the production line is continuous rotary extrusion equipment. It serves to continuously clad steel wire with aluminum so as to produce aluminum clad steel wires which are widely used in electric power transmission, railway electrification systems, and telecommunications fields. Through synchronous extrusion of the aluminum and steel, the aluminum clad steel wire extrusion line is capable of producing steel wires with desired specifications. Our continuous extrusion line is very popular in the power cable production industry, due to its high processing speed as well as the increasing popularity of aluminum clad steel wires in electric power communication field. |

|

Technical Parameters

| Extrusion Method | |

| Single Wheel Double Grooves Tangential Continuous Extrusion | |

| Application Range | |

| Aluminum Cladding Steel Wire | |

| Main Parameters | |

| Nominal Diameter of Extrusion Wheel | Φ350mm |

| Power of Main Motor | 200kW |

| Max. Rotation Speed | 16.7 RPM |

| Average Production Speed | 180m/min |

| End Product Specification | Φ4~ Φ 9mm |

| Leakage Rate | ≤10% |

| Floor Space of Production Line | 8m ×70m |

| Feedstock | |

| Aluminum Rod Diameter | 2~Φ9.5 ± 0.2mm |

| Tensile Strength | ≤ 90 N/mm2 |

| Diameter of Steel Wire | Φ4~ Φ8 mm |

Related:

Continuous Rotary Extrusion Process, Custom Aluminum Extrusions, Continuous Extrusion Equipment Manufacturer

Contact Us

Contact Person: Yiheng Shu

Fax: +86-519-81580370

Add.: No. 279, Huanghe West Road, Xinbei District, Changzhou City, Jiangsu Province