-

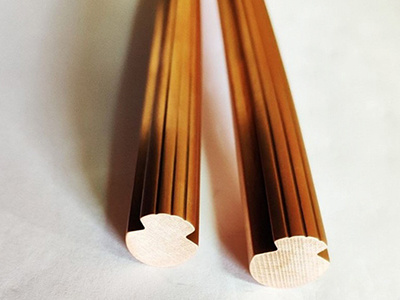

Continuous Extrusion Machine for Copper and Copper Alloy

Continuous Extrusion Machine for Copper and Copper AlloyThe series of copper extrusion lines are mainly composed pay-off system, wire straightener, continuous extrusion machine, cooling system, length counter, take-up stands and electrical control system.

Read More -

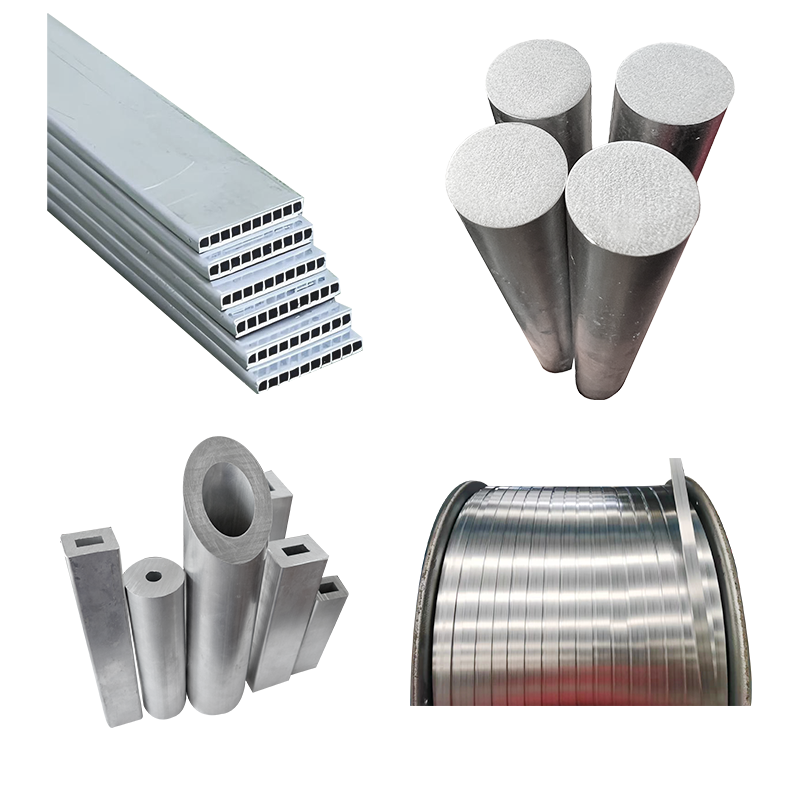

Continuous Extrusion Machine for Aluminum and Aluminum Alloy

Continuous Extrusion Machine for Aluminum and Aluminum AlloyOur continuous extrusion line can be used to extrude different types of aluminum wires, including flat wires, round wires, sector conductors and large aluminum stripes.

Read More -

Continuous Extrusion Cladding

Continuous Extrusion CladdingContinuous extrusion cladding technology is continuous extrusion tangential cladding and it's divided into two processes: direct cladding and indirect cladding.

Read More

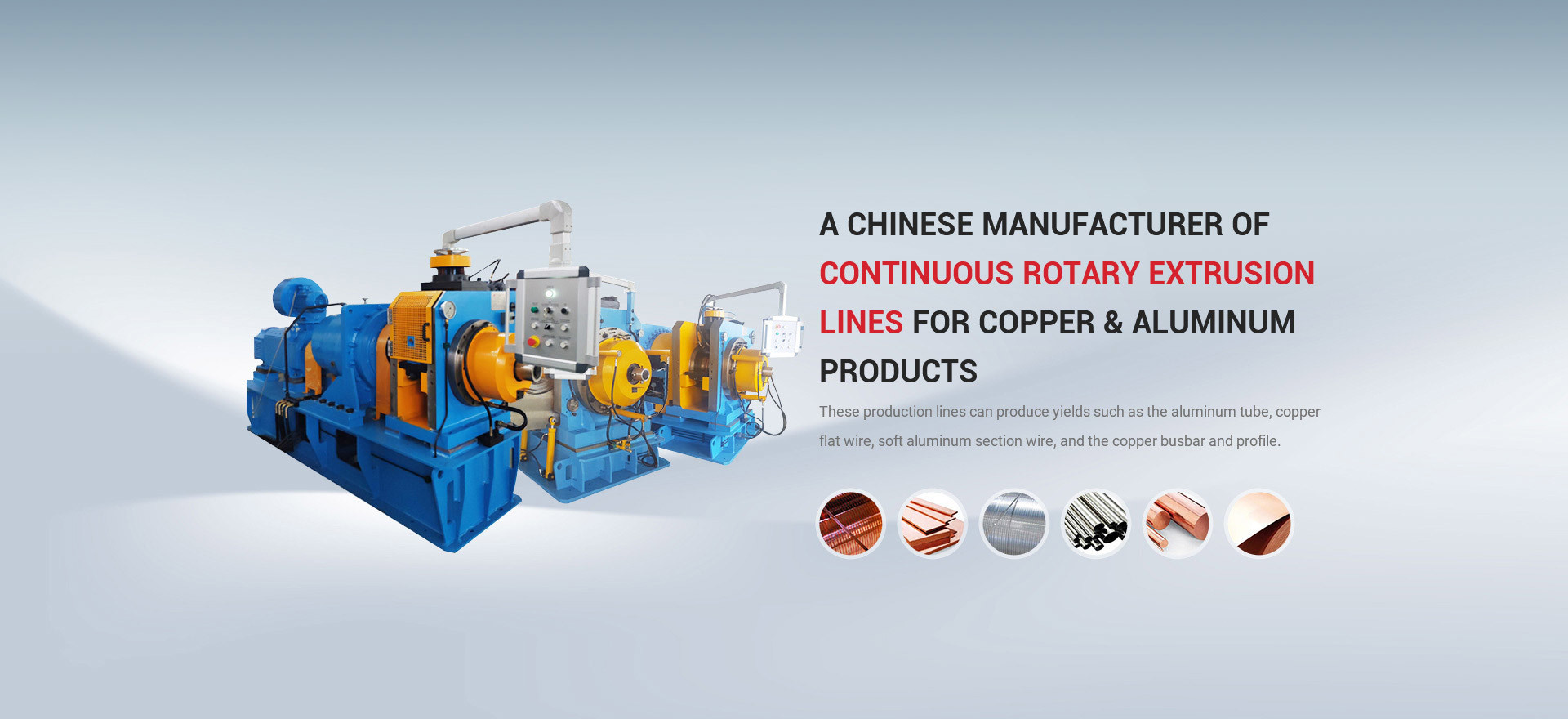

Aibang Machinery & Science Technology

Changzhou Aibang Machinery & Science Technology Co., Ltd. is a Chinese manufacturer of continuous rotary extrusion lines for copper and aluminum products. These production lines are available with different specifications and can produce yields such as the aluminum tube, copper flat wire, soft aluminum section wire, and the copper busbar and profile. Also available are continuous rotary extrusion equipment for producing aluminum clad steel wires.

Our production site covers nearly 9,000㎡, a research and development center accounts for an additional 2,500㎡. The R&D center is equipped with complete sets of precision testing instruments and large-format processing equipment, allowing us to independently develop and manufacture key components.

Cover an area

Technician

Modern equipment

Global service regions

Previous Solutions for Customers

Aibang has been committed to providing customers with outstanding solutions for continuous extrusion equipment.

Continuous Rotary Extrusion Line for Aluminum Tube

We invited customer to visit the production site of continuous rotary extrusion line for aluminum tube of our domestic customers. After seeing the equipment of continuous rotary extrusion line and the extruded products, they decided to discuss customization with us.

Continuous Rotary Extrusion Machine for Aluminum Conductor

Customer visited our factory. After seeing the equipment of continuous rotary extrusion line and the extruded products, they told us their demands. After reaching agreement, we signed a contract.

Continuous Rotary Extrusion Line for Copper Magnesium Alloy Wire

In 2015, after two years' investigation, Elcowire finally chose Changzhou Aibang company as their partner to provide complete process technology and equipment of continuous rotary extrusion line for high-speed rail used copper magnesium alloy wire.

Continuous Rotary Extrusion Equipment for Aluminum Alloy Tube

Customer visited the production sites our domestic customers. Comparing with European equipment, they thought our products were highly cost-effective. Their requirement was that our product must pass pilot production and meet demands.

Technology Advantages

As compared with conventional metal rolling and wire drawing technologies, continuous extrusion equipment has a great number of benefits.

Read MoreShorter Process Flow and Lower Equipment Investment

Lower Energy Consumption; Without Demand for External Heat Source

Low Waste but High First Pass Yield

Low Labor Intensity due to High Automation

Consistent Product Quality

Higher Electric Conductivity for End Products (such as wire, busbar, etc.)

Blog Center

Record the development dynamics of the enterprise and enable exciting sharing

2025-07-17

The 9th China International Wire & Cable Industry Exhibition in 2015

Changzhou Aibang Machinery Technology Co., Ltd. will participate in the 9th China International Wire & Cable Industry Exhibition in Shanghai New International Expo Center from August 29th to September 2nd. Booth number is W4E63. Friends from all walks of life are welcome to visit and guide!

➔2025-07-17

On July 1, 2014, General Manager Shu Bangjun exchanged and cooperated with foreign businessmen and took a group photo

➔2025-07-17

What is continuous extrusion technology?

Continuous extrusion: The die cavity is located on the side of the extrusion wheel, and the blank enters the extrusion cavity under the drive of the rotating extrusion wheel. Under the action of the friction force of the wheel groove, the temperature of the blank rises and the pressure increases.

➔Contact Us

Contact Person: Bangjun Shu

Fax: +86-519-81580370

Add.: No. 279, Huanghe West Road, Xinbei District, Changzhou City, Jiangsu Province